Hey, this is the 11th update on

my SolidWorks blog

The Lego man has finally been completed,

with a few struggles on the hand.

After completing the hips relatively easily

I moved on to my final piece of the Lego man.

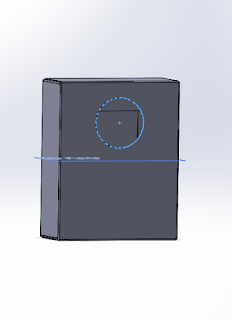

I started off with a simple sketch of the

hand to get the shape of the hand, at a closer look I realised that the part of

the hand that goes in to the arm goes off on an angle. I decided that to get

the right angle and shape I should scan the hand in and use the image as a

reference. I then using the reference sketches started with the fingers and

worked my way down.

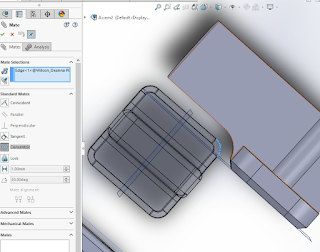

After this I began to sub assemble the Lego

man and finally go to put it all together.

Till next time,

Deanna (design student)

Deanna (design student)